Hauschild SpeedMixer

The Original Pioneer of Centrifuge Mixing

Say YES to an Authentic SpeedMixer - Choose The Genuine SpeedMixer Trusted Globally

SMART DAC 250-2000

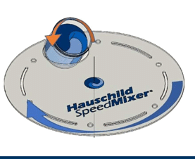

The SMART DAC series is the latest generation of Hauschild SpeedMixer® equipment. This new class of DAC equipment delivers the largest advancement in mixing power, process monitoring & control, and data collection since the previous generation was launched in 2010.

The fully customizable SMART DAC platform is the foundation of the most versatile and capable DAC mixing equipment to date. With options like live temperature monitoring & control (with active cooling), independent control of main rotation/counterrotation, and a manufacturing or research optimized interface, it is already answering many of the most common requests from industry. The platform was also designed with the future in mind. The machine’s software and onboard PLC allow easy connection and integration of nearly any sensor imaginable as well as IOT compatibility.

Innovation. Reputation. Trust.

Top Features

- The Most (or least) Powerful Bladeless Mixing Available

- Intuitive customizable user interface

- Stroboscopic Process Monitoring

SMART DAC equipment was designed with the power and ruggedization to offer the highest main RPM in its class and also has the stability balance to allow the main rotation to be set as low as 50RPM. This gives the user the widest range of control that has ever been available.

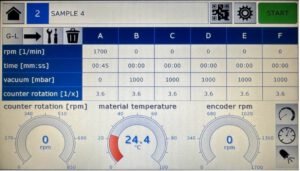

The machine’s touchscreen interface makes it easy to create programs and customize the display to show the most relevant information about the mixing process. This ensures that precisely optimized mixing and degassing methods can be accurately and repeatably reproduced. With minimal training, any operator can achieve exactly the same results. The optional software packages allow remote control of the equipment from any PC, tablet, or smartphone as well as full documentation of all mixing activities for traceability purposes.

The integrated LED light can be set to remain on, off, or to flash at the same frequency as the main RPM and function as a stroboscope. When the light is used as a stroboscope, it gives the illusion that the cup is standing still, and mixing/degassing progress can be monitored live through the viewing window. The visual feedback can help the operator quickly optimize a process by seeing how much speed is required to move the material, when the material is fully mixed, and exactly when the material is fully degassed.

The integrated LED light can be set to remain on, off, or to flash at the same frequency as the main RPM and function as a stroboscope. When the light is used as a stroboscope, it gives the illusion that the cup is standing still, and mixing/degassing progress can be monitored live through the viewing window. The visual feedback can help the operator quickly optimize a process by seeing how much speed is required to move the material, when the material is fully mixed, and exactly when the material is fully degassed.

Additional Features

Temperature monitoring

& control

Active Cooling

Variable Counterrotation

Manufacturing package

Data logging software

Engineering proven in the field to last for decades

Built with safety features that meet or exceed industry standards & requirements (NRTL field labeling optional)

Ergonomic design continually optimize based on user feedback since 1973

Compatible with hundreds of accessories to help optimize performance for your application(s)

Customizable for innovative applications that require innovative solutions

The Hauschild team will support you in selecting the best machine and accessories for your application.

As a Hauschild customer you will also receive training and technical support from our technical staff.

Case Study

Enhancing Processing Efficiency with Hauschild SpeedMixer® Technology

The R&D lab of a ceramics company was having issues with wasted time & material as well as with the quality of their lab scale batches. The planetary ball mill they were using to mix & disperse took hours or sometimes days to produce samples. The ball mill required large amounts of material, much of which was lost because it was too difficult to separate from the grinding media. They also noticed that their material contained a great deal of entrained air and that their densities and physical properties were typically significantly less than the theoretical values.

Finally, the team discovered the Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P. By using a higher counterrotation ratio with the machine’s variable counterrotation function, they were able to deagglomerate and disperse powders into a slurry in minutes rather than hours. Because the SMART DAC had more batch size flexibility and didn’t require grinding balls, they could also mix smaller batches and waste less material. The DAC motion and vacuum function also easily removed entrapped air from the material unlocking the material properties that they had been targeting.

The team loved their new Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P not only because it was faster and delivered better results, but also because they could mix in disposable cups and didn’t have to do any cleaning!

Enhancing Efficiency and Quality in Ceramics R&D with Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P

This case study explores how a ceramics company’s research and development (R&D) laboratory overcame challenges related to wasted time, material, and subpar quality of lab scale batches. The company successfully addressed these issues by adopting the Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P, which revolutionized their mixing and dispersion processes.

Time and Material Waste: The existing planetary ball mill employed by the lab for mixing and dispersing materials required excessive time, often taking hours or even days to produce samples. Additionally, large amounts of material were lost when separating out the grinding media, leading to significant waste.

Inconsistent Quality: The lab observed that the physical properties and densities of their ceramic materials sometimes deviated significantly from the theoretical values. This discrepancy was attributed to the presence of entrained air within the material, affecting the overall quality.

Discovering the Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P: After diligent research and evaluation, the R&D team discovered the Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P, a cutting-edge solution that addressed their specific needs.

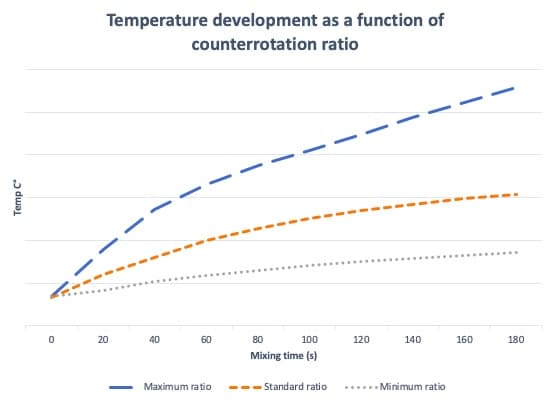

Reduction of processing time: By taking advantage of its variable counterrotation function, the team used a higher than normal counterrotation ratio to achieve rapid deagglomeration and dispersion of powders into a slurry. The SpeedMixer significantly reduced processing time, transforming the task from hours to minutes.

Enhanced Flexibility and Reduced Material Utilization: Unlike the ball mill, the SMART DAC offered more batch size flexibility. The equipment’s compatibility with a variety of disposable mixing vessels allowed the team to mix smaller batches, reducing material waste significantly. Moreover, the SpeedMixer did not require grinding balls in this case which ensured there was negligible loss of materials.

Removal of entrapped air and bubbles: The DAC motion and vacuum function eliminated entrapped air from the ceramic material during the mixing process. This breakthrough enabled the team to unlock the targeted material properties that had previously been elusive, resulting in improved densities and physical characteristics aligning closely with theoretical values.

The ceramics company’s R&D lab successfully addressed their challenges of wasted time, material, and inconsistent quality by implementing the Hauschild SpeedMixer® SMART DAC 1100.4 VAC-P. The SpeedMixer’s modern features and capabilities, flexibility, and operational convenience proved pivotal in transforming their material processing procedures. This case study exemplifies how adopting innovative equipment can lead to significant improvements in efficiency, material utilization, and product quality within the ceramics industry.

Unmatched Laboratory Mixing Innovation

Secondary features and benefits - value

Temperature control package

The Temperature Control package for the Hauschild SpeedMixer® SMART DAC series provides a number of new and novel capabilities. The machine uses a non-contact sensor to provide Live Temperature Monitoring. The live temperature data can be used by the SMART software to provide Temperature Control by varying process parameters accordingly. This includes the option to apply Active Cooling directly to the mixing vessel.

Variable Counterrotation Package

Until recently, no high-power DAC mixer on the market offered independent control of the main rotation and counter rotation of the mixing vessel. The most powerful DAC mixer ever offered is now also available with a digitally programmable Variable Counterrotation Ratio. This gives the user the option to favor mixing or Dearing/degassing and gives significantly more control over the temperature of the material.

Featured Accessories

Numerous Options

Depending on the mixing weight and feeling volume different cups are available for your Hauschild SpeedMixer®. All mixing cups can be used as disposable items. Hot child offers jars in several colors, beside transparent, white and black, which is suitable for photo sensitive material. The most used jars are made of polypropylene (PP) due to its high resistance to the temperature and the low chemical reactivity. Dimensions of the cups and buckets go from few ml to up to 16l of normal capacity.

- PP 50, 100, 250, 300, 1200, 2000

- Max 40, 60, 100, 200, 300

- Stainless Steel 30, 100, 500, 1000

Standard and Customized

To help the customers obtaining the best results with their Hauschild SpeedMixer®, we continuously work on the research and development of accessories. Custom made adapters have been designed to allow our customers mixing in a wide range of small and large container such as poly propylene jars, syringes, cartridges, glass, bottles, and customized containers. Our solutions allow mixing in one or more containers for every run. We are pleased to help you.have been designed to allow our customers mixing in a wide range of small and large container such as poly propylene jars, syringes, cartridges, glass, bottles, and customized containers. Our solutions allow mixing in one or more containers for every run. We are pleased to help you finding the best suitable accessory for your machine.

- PP 50, 100, 250, 300, 1200, 2000

- Max 40, 60, 100, 200, 300

- Multi holders

- Cartridge & syringe holders

- Vial holder

Accessories

- Lever Press

- SpeedDisks

- Rings

- Cylinders

- Spherical media

Technical specs & capability comparison

Criteria | Hauschild SpeedMixer DAC | Hauschild SpeedMixer SMART DAC | Thinky Mixers | Mazerustar (Kurabo) Mixers | FlackTek Mixer |

Inventor of the DAC (Dual Asymmetric Centrifuge) technology. | Yes | No | No | No | |

Original technology patent. | Yes | No | No | No | |

In the market since. | 1974 | 2021 | 1984[1] | 1990 | 2020 |

Field tested technology. | 49 years[2] | 39 years | 33 years | 3 years | |

Mixing weight (grams). | Up to 10.000 | Up to 2.000[3] | Up to 2×10.000 | Up to 2×10.000 | Up to 2×10.000 |

Lab-size 2kg machine | No | Yes | Yes | Yes | No5 |

Programmable/Programs. | Up to 50 | Up to 500 | Up to 250 | ||

Remote operation. | Yes | ??? | ??? | Yes | |

Independent variable counterrotation[4]. | No | Yes | No5 | No5 | No5 |

Real time material’s temperature reading. | No | Yes | No[5] | No5 | No5 |

Automatic material’s temperature control. | No | Yes | No5 | No5 | No5 |

Automatic material cooling system. | No | Yes | No5 | No5 | No5 |

Mixing under vacuum | Yes | Yes | Yes | Yes | |

Robotic version. | Yes | Yes | Yes | Yes | |

Vacuum robotic version. | No | Yes | No5 | No5 | No5 |

Integrated automatic strobe-light | No | Yes | No5 | No5 | Custom solution |

Warranty period (months) | 12 | 12 | 12 | 6 to 12 | |

Expected lifetime | 20+ years | Unknown | Unknown | Unknown | |

Made in … | Germany | Japan | Japan | USA | |

Type of company | Traditional family business | Corporation | Public | Single owner | |

Ownership | Germany | Japan | Japan | UK | |

Local presence with technical support |

|

|

|

|

|

[1] The company was founded in 1971 and, according to the website, the development of the mixer took 13 years.

[2] The DAC and the SMART DAC share the same core technology.

[3] Soon available also up to 10kg.

[4] With separate, dedicated servomotor.

[5] No evidence was found about this feature.

| Model | SMART DAC 250.3 FVZ-LR | SMART DAC 400.3 FVZ-LR | SMART DAC 600.3 FVZ-LR | SMART DAC 700.3 FVZ-LR | SMART DAC 800.3 FVZ-LR | SMART DAC 1100.3 FVZ | SMART DAC 1500.3 FVZ | SMART DAC 2000.3 FVZ |

| Small samples | Small samples | All around lab use | High viscosity & high SG | High viscosity & high SG | Larger lab scale batches high SG | Larger lab scale batches high SG | Larger lab scale batches high SG | |

| Commonly used for | Very high viscosities (>5M cps) | Very high viscosities (>5M cps) | Specific gravity ~0.8 – 1.5 g/cc | Specific gravity ~1.5 – 2 g/cc | Specific gravity > ~2 g/cc | Specialty manufacturing | Specialty manufacturing | Specialty manufacturing |

| High speed milling | High speed milling | Production batches up to 500g | Mixing in stainless containers | |||||

| Performance | ||||||||

| Mixing speed – RPM | 50 – 2500 | 50 – 2400 | 50 – 2200 | 50 – 2000 | 50 – 1850 | 50 – 1700 | 50 – 1400 | 50 – 1200 |

| Gross mixing capacity | up to 250 g (0.55 lb.) | up to 400 g (0.88 lb.) | up to 600 g (1.32 lb.) | up to 700 g (1.54 lb.) | up to 800 g (1.76 lb.) | up to 1100 g (2.43 lb.) | up to 1500 g (3.31 lb.) | up to 2000 g (4.41 lb.) |

| Largest container volume | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) |

| Smallest container volume | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) |

| Programs | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) |

| Mixing zones per program | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) |

| Max runtime per cycle | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) |

| Adjustable counterweight | Available | Available | Available | Available | Available | ✓ | ✓ | ✓ |

| Design | ||||||||

| User interface | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) |

| Width | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) |

| Width on console | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) |

| Height (lid closed) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) |

| Height (lid open) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) |

| Height on console (lid closed) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) |

| Height on console (lid open) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) |

| Depth | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) |

| Depth on console | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) |

| Weight | 106 kg (233,73 lb.) | 110 kg (242,55 lb.) | 112 kg (246,96 lb.) | 114 kg (251,37 lb.) | 116 kg (255,78 lb.) | 118 kg (260,19 lb.) | 120 kg (264,6 lb.) | 125 kg (275,62 lb.) |

| Input Power | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V |

| Peak power consumption | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W |

| Vacuum interface | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. |

| Capabilities | ||||||||

| Liquid mixing (< ~300k cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Paste mixing (> ~300k cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| High viscosity mixing (> ~10M cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Powder mixing | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with paste | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix powder with paste | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with powder | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mixing multiple samples at once | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Dispersion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Milling & pulverization | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Stroboscopic process monitoring | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Live material temperature monitoring | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package |

| Cooling & temperature control | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package |

| Variable counterrotation | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package |

| Manufacturing optimized interface | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package |

| Deairing & bubble removal | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Vacuum degassing | No | No | No | No | No | No | No | No |

| Cartridge deairing | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Syringe deairing (1 or multiple) | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Model | SMART DAC 250.4 VAC-P LR | SMART DAC 400.4 VAC-P LR | SMART DAC 600.4 VAC-P LR | SMART DAC 700.4 VAC-P LR | SMART DAC 800.4 VAC-P LR | SMART DAC 1100.4 VAC-P | SMART DAC 1500.4 VAC-P | SMART DAC 2000.4 VAC-P |

| Small samples | Small samples | All around lab use | High viscosity & high SG | High viscosity & high SG | Larger lab scale batches high SG | Larger lab scale batches high SG | Larger lab scale batches high SG | |

| Commonly used for | Very high viscosities (>5M cps) | Very high viscosities (>5M cps) | Specific gravity ~0.8 – 1.5 g/cc | Specific gravity ~1.5 – 2 g/cc | Specific gravity > ~2 g/cc | Specialty manufacturing | Specialty manufacturing | Specialty manufacturing |

| Degassing syringes/cartridges | Degassing syringes/cartridges | Production batches up to 500g | Mixing in stainless containers | |||||

| Performance | ||||||||

| Mixing speed – RPM | 50 – 2500 | 50 – 2400 | 50 – 2200 | 50 – 2000 | 50 – 1850 | 50 – 1700 | 50 – 1400 | 50 – 1200 |

| Gross mixing capacity | up to 250 g (0.55 lb.) | up to 400 g (0.88 lb.) | up to 600 g (1.32 lb.) | up to 700 g (1.54 lb.) | up to 800 g (1.76 lb.) | up to 1100 g (2.43 lb.) | up to 1500 g (3.31 lb.) | up to 2000 g (4.41 lb.) |

| Largest container volume | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) | 2800 ml (0,74 gal) |

| Smallest container volume | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) |

| Programs | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) | 300 (500 Pro Version) |

| Mixing zones per program | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) | 6 (12 to 36 Pro Version) |

| Max runtime per cycle | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) | 10 min. (30 min. Pro Version) |

| Adjustable counterweight | Available | Available | Available | Available | Available | ✓ | ✓ | ✓ |

| Design | ||||||||

| User interface | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) | Touchscreen 7″ (10″ Optional) |

| Width | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) | 650 mm (25,59″) |

| Width on console | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) | 740 mm (29,13″) |

| Height (lid closed) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) | 610 mm (24,01″) |

| Height (lid open) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) | 970 mm (38,18″) |

| Height on console (lid closed) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) | 1180 mm (46,45″) |

| Height on console (lid open) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) | 1540 mm (60,62″) |

| Depth | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) | 620 mm (24,4″) |

| Depth on console | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) | 670 mm (26,37″) |

| Weight | 108 kg (238,14 lb.) | 120 kg (264,6 lb.) | 122 kg (269,01 lb.) | 124 kg (273,42 lb.) | 126 kg (277,83 lb.) | 128 kg (282,24 lb.) | 130 kg (286,65 lb.) | 135 kg (297,67 lb.) |

| Input Power | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V |

| Peak power consumption | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W | 1500W |

| Vacuum interface | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT |

| Capabilities | ||||||||

| Liquid mixing (< ~300k cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Paste mixing (> ~300k cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| High viscosity mixing (> ~10M cps) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Powder mixing | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with paste | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix powder with paste | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with powder | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Mixing multiple samples at once | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Dispersion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Milling & pulverization | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Stroboscopic process monitoring | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Live material temperature monitoring | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package |

| Cooling & temperature control | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package | Temperature package |

| Variable counterrotation | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package | Counterrotation package |

| Manufacturing optimized interface | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package | Manufacturing package |

| Deairing & bubble removal | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Vacuum degassing | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Cartridge deairing | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |

| Syringe deairing (1 or multiple) | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory | Accessory |