Hauschild SpeedMixer

The Original Pioneer of Centrifuge Mixing

Say YES to an Authentic SpeedMixer - Choose The Genuine SpeedMixer Trusted Globally

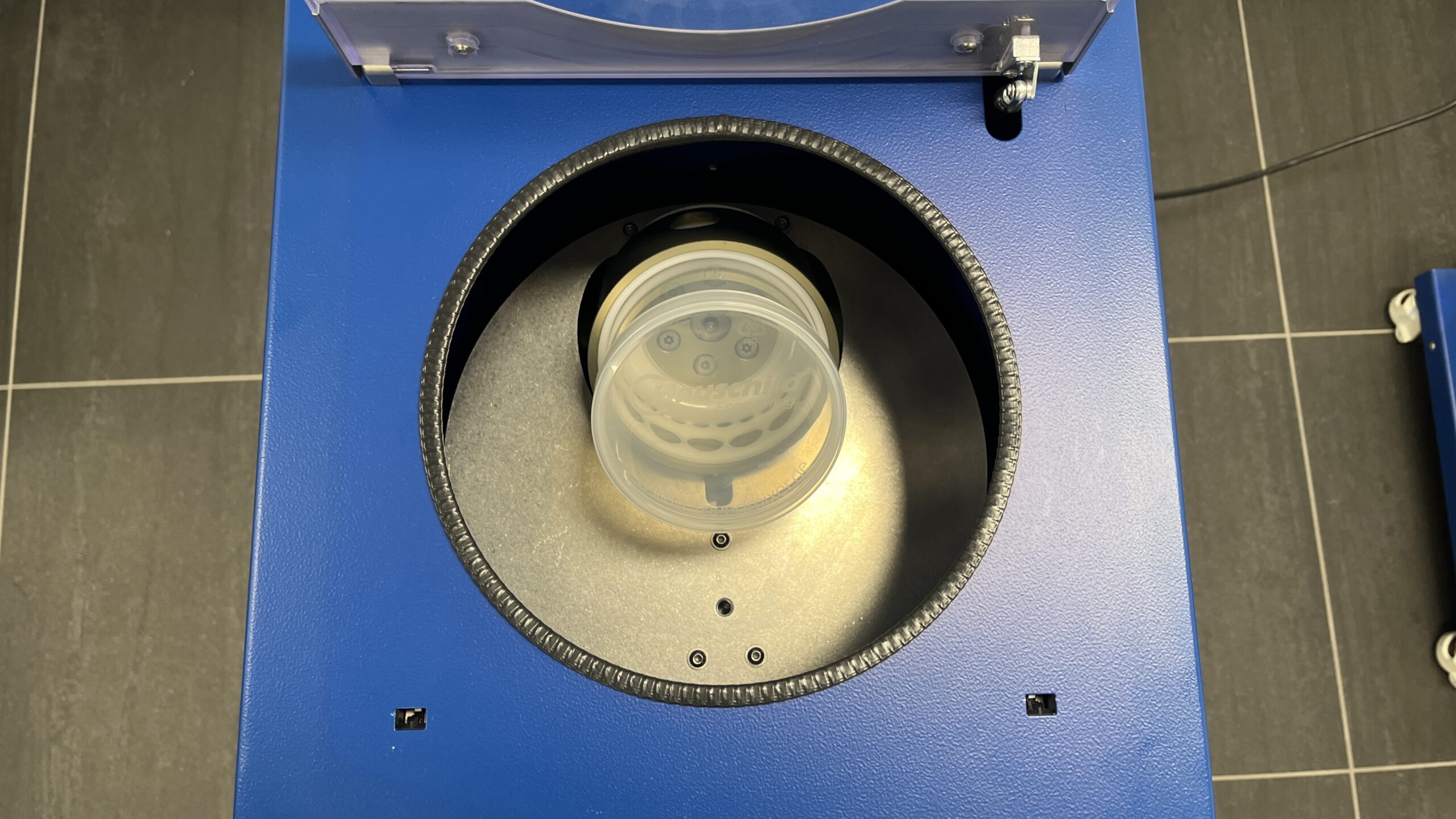

DAC M-Series LR 400-800

The Hauschild SpeedMixer® LR series, first introduced in 2010, is widely used to mix silicones, epoxies, urethanes, ceramic & battery slurries, pharmaceuticals, and many other materials. This series is also available with the ability to vacuum degas while mixing or mix under inert conditions. Its Modern geometry, high main RPM, programmability, and configurability/compatibility with accessories make a versatile laboratory mixer. These features also give the equipment the precision, repeatability, and process control needed to handle specialty production applications.

Innovation. Reputation. Trust.

Top Features

Dual Asymmetrical Centrifugal (DAC) mixing – A closed disposable container is rotated around a primary axis. The container is simultaneously counterrotated around on its own Y axis, creating a powerful mixing vortex. This result is fast, homogeneous, repeatable mixing and bubble removal.

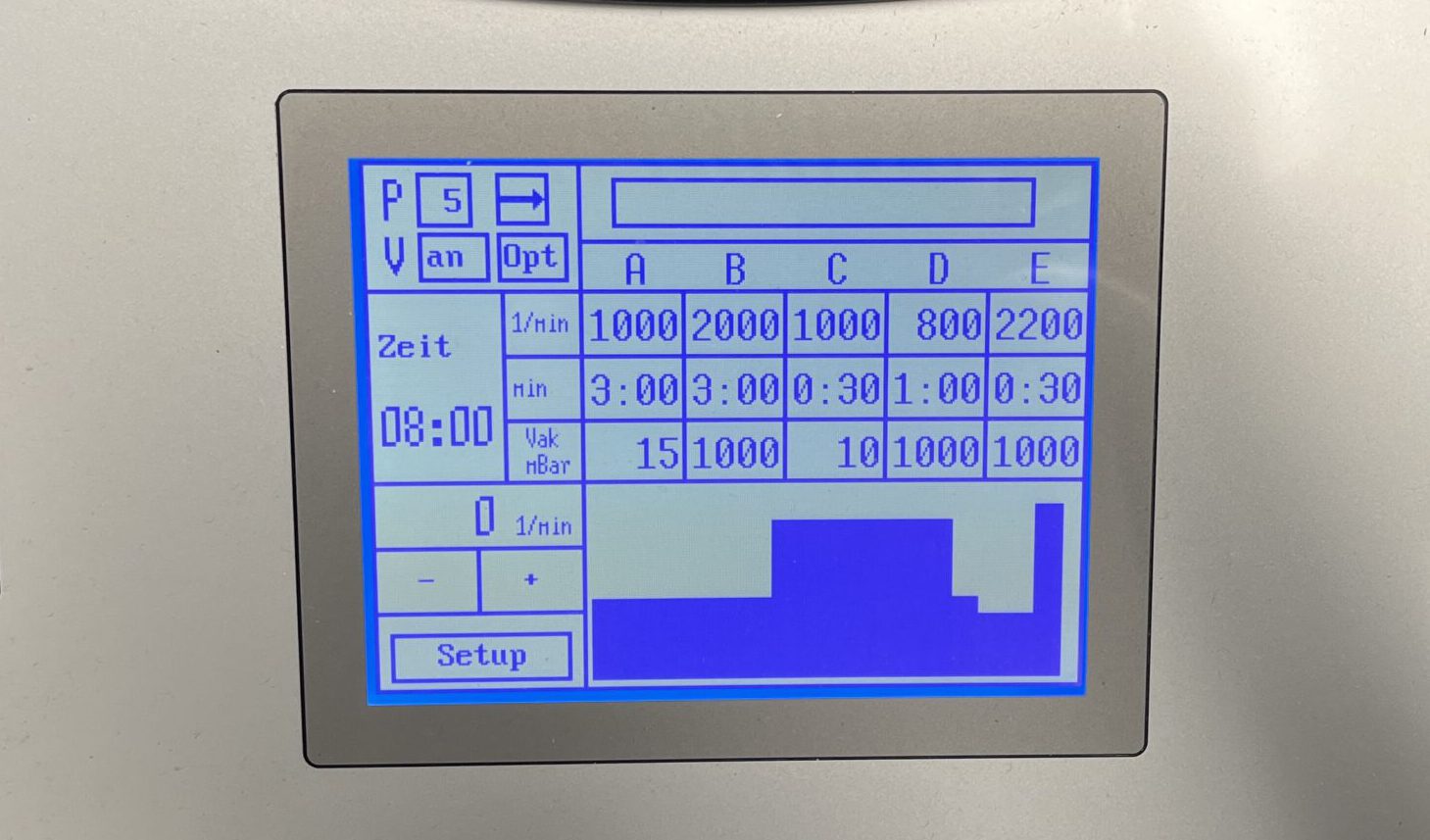

The machine’s touchscreen display makes it easy to set, save, and lock programs. This ensures that precisely optimized mixing and degassing methods can be accurately and repeatably reproduced. With minimal training, any operator can achieve exactly the same results. The optional PC interface software allows remote control of the equipment full documentation of all mixing activities for traceability purposes.

VAC series Hauschild SpeedMixer® equipment features the ability to pull and regulate vacuum throughout the process. This removes microbubbles, dissolved air, and can even strip volatile content or purge solvent. The centrifugal motion combined with constant exposure of new surface area makes the process much faster than conventional vacuum degassing methods. It also helps prevent messy boil-overs. The equipment is compatible with any vacuum source and will automatically power & control vacuum pumps up to 700W.

VAC series Hauschild SpeedMixer® equipment features the ability to pull and regulate vacuum throughout the process. This removes microbubbles, dissolved air, and can even strip volatile content or purge solvent. The centrifugal motion combined with constant exposure of new surface area makes the process much faster than conventional vacuum degassing methods. It also helps prevent messy boil-overs. The equipment is compatible with any vacuum source and will automatically power & control vacuum pumps up to 700W.

Additional Features

Live temperature monitoring and control

Active Cooling

Variable Counterrotation

Data logging software

Manufacturing Optimized Interface

Engineering proven in the field to last for decades

Built with safety features that meet or exceed industry standards & requirements (NRTL field labeling optional)

Ergonomic design continually optimize based on user feedback since 1973

Compatible with hundreds of accessories to help optimize performance for your application(s)

Customizable for innovative applications that require innovative solutions

The Hauschild team will support you in selecting the best machine and accessories for your application.

As a Hauschild customer you will also receive training and technical support from our technical staff.

Case Study

Hauschild SpeedMixer® DAC 600.2 VAC-P LR Helps Defense Customer Eliminate Bubbles and Improve Adhesive Properties

Undermixing: Because hand-mixing is a common practice, undermixing is a common issue with epoxy-based adhesives. Multi-component adhesives require a thorough mixing to ensure homogeneity and that the material cures/reacts properly. The Hauschild SpeedMixer® uses a high-speed DAC mixing action to quickly and effectively homogenize the adhesive components and any additives, if used.

Bubbles: Bubbles can form in epoxy-based adhesives during a conventional mixing process, which can weaken the bond and reduce the adhesive’s overall performance. The Hauschild SpeedMixer® uses DAC mixing with or without vacuum to remove air bubbles, ensuring that the adhesive cures properly and forms a strong, durable bond.

Volatile Content: Volatile content refers to any solvents or other volatile compounds that are present in the adhesive mixture. These compounds can expand and form bubbles during the curing process, leading to voids and weak points in the adhesive bond. The Hauschild SpeedMixer® uses a vacuum degassing step to remove unwanted volatile content that could create bubbles during the cure, or potentially outgas and cause issues in space based applications.

Dissolved Air: Dissolved air can also weaken the adhesive bond, as it can cause bubbles to form during the curing process. The Hauschild SpeedMixer® uses a vacuum mixing technique to remove dissolved air from the adhesive mixture. This ensures that the adhesive cures properly and that the cure process can be accelerated with heat without creating bubbles.

The implementation of the Hauschild SpeedMixer® DAC 600.2 VAC-P LR provided the customer with several benefits. The new standardized and automated process eliminated the formation of bubbles during the heat-accelerated cure process, resulting in the elimination of costly re-works and scrap parts. The improved dispersion of the Aerosil resulted in a stronger bond between the adhesive and the part. Additionally, the operators were provided with additional working time, allowing them to complete the process more efficiently.

The operators also noted that they liked that the new process didn’t make any messes, and there was nothing to clean after mixing. This saved time and increased the efficiency of the overall process.

Unmatched Laboratory Mixing Innovation

Secondary features and benefits - value

Best in class performance, reliability, and value

Since inventing the technology in 1974, the team at Hauschild have been engineering and manufacturing with a focus on quality, performance, safety, and reliability. Hauschild SpeedMixer® equipment is known for being the most powerful, versatile, and safe lab mixer / specialty production mixer available. It is also one of the few planetary centrifugal mixers that has been proven in the field to last for decades with minimal maintenance.

Saves time & material – Protects the workforce

- The Hauschild SpeedMixer® mixes quickly and is compatible with a variety of single use mixing cups. This saves time associated with mixing, as well as time, solvents, and other materials associated with cleanup. Unlike blade mixers, DAC mixers offer the ability to size batches/mixing containers based on what is needed for testing. This eliminates significant material waste.

- Conventional mixing equipment & methods present several hazards to the workforce such as exposure to material, exposure to cleaning solvents / solvent vapors, and risk of repetitive strain injury (RSI). An automated mixing process utilizing Hauschild SpeedMixer® equipment, along with proper PPE and material handling practices, protect the operator from these sources of danger and can help reduce the rick of a Lost Time Injury (LTI).

Featured Accessories

Numerous Options

Depending on the mixing weight and feeling volume different cups are available for your Hauschild SpeedMixer®. All mixing cups can be used as disposable items. Hot child offers jars in several colors, beside transparent, white and black, which is suitable for photo sensitive material. The most used jars are made of polypropylene (PP) due to its high resistance to the temperature and the low chemical reactivity. Dimensions of the cups and buckets go from few ml to up to 16l of normal capacity.

- PP 50, 100, 250, 300

- Max 40, 60, 100, 200, 300

- Stainless Steel 30, 100, 500, 1000

Standard and Customized

To help the customers obtaining the best results with their Hauschild SpeedMixer®, we continuously work on the research and development of accessories. Custom made adapters have been designed to allow our customers mixing in a wide range of small and large container such as poly propylene jars, syringes, cartridges, glass, bottles, and customized containers. Our solutions allow mixing in one or more containers for every run. We are pleased to help you.have been designed to allow our customers mixing in a wide range of small and large container such as poly propylene jars, syringes, cartridges, glass, bottles, and customized containers. Our solutions allow mixing in one or more containers for every run. We are pleased to help you finding the best suitable accessory for your machine.

- PP 50, 100, 250, 300

- Max 40, 60, 100, 200

- Multi holders

- Cartridge & syringe holders

- Vial holder

- Lever Press

- SpeedDisks

- Rings

- Cylinders

- Spherical media

Specialty Production SERIES

Technical specs & capability comparison

Criteria | Hauschild SpeedMixer DAC | Hauschild SpeedMixer SMART DAC | Thinky Mixers | Mazerustar (Kurabo) Mixers | FlackTek Mixer |

Inventor of the DAC (Dual Asymmetric Centrifuge) technology. | Yes | No | No | No | |

Original technology patent. | Yes | No | No | No | |

In the market since. | 1974 | 2021 | 1984[1] | 1990 | 2020 |

Field tested technology. | 49 years[2] | 39 years | 33 years | 3 years | |

Mixing weight (grams). | Up to 10.000 | Up to 2.000[3] | Up to 2×10.000 | Up to 2×10.000 | Up to 2×10.000 |

Lab-size 2kg machine | No | Yes | Yes | Yes | No5 |

Programmable/Programs. | Up to 50 | Up to 500 | Up to 250 | ||

Remote operation. | Yes | ??? | ??? | Yes | |

Independent variable counterrotation[4]. | No | Yes | No5 | No5 | No5 |

Real time material’s temperature reading. | No | Yes | No[5] | No5 | No5 |

Automatic material’s temperature control. | No | Yes | No5 | No5 | No5 |

Automatic material cooling system. | No | Yes | No5 | No5 | No5 |

Mixing under vacuum | Yes | Yes | Yes | Yes | |

Robotic version. | Yes | Yes | Yes | Yes | |

Vacuum robotic version. | No | Yes | No5 | No5 | No5 |

Integrated automatic strobe-light | No | Yes | No5 | No5 | Custom solution |

Warranty period (months) | 12 | 12 | 12 | 6 to 12 | |

Expected lifetime | 20+ years | Unknown | Unknown | Unknown | |

Made in … | Germany | Japan | Japan | USA | |

Type of company | Traditional family business | Corporation | Public | Single owner | |

Ownership | Germany | Japan | Japan | UK | |

Local presence with technical support | |||||

[1] The company was founded in 1971 and, according to the website, the development of the mixer took 13 years.

[2] The DAC and the SMART DAC share the same core technology.

[3] Soon available also up to 10kg.

[4] With separate, dedicated servomotor.

[5] No evidence was found about this feature.

| Model | DAC 400.1 FVZ-LR | DAC 600.1 FVZ-LR | DAC 700.1 FVZ LR | DAC 800.1 FVZ-LR |

| Small samples | All around lab use | High viscosity & high SG | High SG | |

| Commonly used for | Low bulk density materials | Specific gravity ~0.8 – 1.5 g/cc | Specific gravity ~1.5 – 2 g/cc | Specific gravity > ~2 g/cc |

| High speed milling | Production batches up to 500g | Mixing in stainless containers | ||

| Performance | ||||

| Mixing speed – RPM | 800 – 2300 | 800 – 2100 | 800 – 1850 | 800 – 1750 |

| Gross mixing capacity | up to 400 g (0.88 lb.) | up to 600 g (1.32 lb.) | up to 700 g (1.54 lb.) | up to 800 g (1.76 lb.) |

| Largest container volume | 2000 ml (0,53 gal) | 2000 ml (0,53 gal) | 2000 ml (0,53 gal) | 2000 ml (0,53 gal) |

| Smallest container volume | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) |

| Programs | 20 | 20 | 20 | 20 |

| Mixing zones per program | 5 | 5 | 5 | 5 |

| Max runtime per cycle | 10 min. | 10 min. | 10 min. | 10 min. |

| Adjustable counterweight | Available | Available | Available | Available |

| Design | ||||

| User interface | Touchscreen | Touchscreen | Touchscreen | Touchscreen |

| Width | 440 mm (17,32″) | 440 mm (17,32″) | 440 mm (17,32″) | 440 mm (17,32″) |

| Width on console | 445 mm (17,51″) | 445 mm (17,51″) | 445 mm (17,51″) | 445 mm (17,51″) |

| Height (lid closed) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) |

| Height (lid open) | 960 mm (37,79″) | 960 mm (37,79″) | 960 mm (37,79″) | 960 mm (37,79″) |

| Height on console (lid closed) | 1135 mm (44,68″) | 1135 mm (44,68″) | 1135 mm (44,68″) | 1135 mm (44,68″) |

| Height on console (lid open) | 1455 mm (57,28″) | 1455 mm (57,28″) | 1455 mm (57,28″) | 1455 mm (57,28″) |

| Depth | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) |

| Depth on console | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) |

| Weight | 76/167 (kg/lb) | 76/167 (kg/lb) | 78/172 (kg/lb) | 91/200 (kg/lb) |

| Input Power | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V |

| Peak power consumption | 1200W | 1200W | 1200W | 1200W |

| Vacuum interface | N.A. | N.A. | N.A. | N.A. |

| Capabilities | ||||

| Liquid mixing (< ~300k cps) | ✓ | ✓ | ✓ | ✓ |

| Paste mixing (> ~300k cps) | ✓ | ✓ | ✓ | ✓ |

| High viscosity mixing (> ~10M cps) | ✓ | ✓ | ✓ | ✓ |

| Powder mixing | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with paste | ✓ | ✓ | ✓ | ✓ |

| Mix powder with paste | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with powder | ✓ | ✓ | ✓ | ✓ |

| Mixing multiple samples at once | Accessory | Accessory | Accessory | Accessory |

| Dispersion | ✓ | ✓ | ✓ | ✓ |

| Milling & pulverization | Accessory | Accessory | Accessory | Accessory |

| Stroboscopic process monitoring | No | No | No | No |

| Live material temperature monitoring | No | No | No | No |

| Cooling & temperature control | No | No | No | No |

| Variable counterrotation | No | No | No | No |

| Manufacturing optimized interface | No | No | No | No |

| Deairing & bubble removal | ✓ | ✓ | ✓ | ✓ |

| Vacuum degassing | No | No | No | No |

| Cartridge deairing | Accessory | Accessory | Accessory | Accessory |

| Syringe deairing (1 or multiple) | Accessory | Accessory | Accessory | Accessory |

| Model | DAC 400.2 VAC-P LR | DAC 600.2 VAC-P LR | DAC 700.2 VAC-P LR | DAC 800.2 VAC-P LR |

| Small samples | All around lab work | High viscosity & high SG | High SG | |

| Commonly used for | Low bulk density materials | Specific gravity ~0.8 – 1.5 g/cc | Specific gravity ~1.5 – 2 g/cc | Specific gravity > ~2 g/cc |

| High speed milling | Production batches up to 500g | Mixing in stainless containers | ||

| Performance | ||||

| Mixing speed – RPM | 800 – 2300 | 800 – 2100 | 800 – 1850 | 800 – 1750 |

| Gross mixing capacity | up to 400 g (0.88 lb.) | up to 600 g (1.32 lb.) | up to 700 g (1.54 lb.) | up to 800 g (1.76 lb.) |

| Largest container volume | 1500 ml (0,4 gal) | 1500 ml (0,4 gal) | 1500 ml (0,4 gal) | 1500 ml (0,4 gal) |

| Smallest container volume | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) | <10ml (0.003 gal) |

| Programs | 20 | 20 | 20 | 20 |

| Mixing zones per program | 5 | 5 | 5 | 5 |

| Max runtime per cycle | 10 min. | 10 min. | 10 min. | 10 min. |

| Adjustable counterweight | Available | Available | Available | Available |

| Design | ||||

| User interface | Touchscreen | Touchscreen | Touchscreen | Touchscreen |

| Width | 440 mm (17,32″) | 440 mm (17,32″) | 440 mm (17,32″) | 440 mm (17,32″) |

| Width on console | 445 mm (17,51″) | 445 mm (17,51″) | 445 mm (17,51″) | 445 mm (17,51″) |

| Height (lid closed) | 730 mm (28,74″) | 730 mm (28,74″) | 730 mm (28,74″) | 730 mm (28,74″) |

| Height (lid open) | 1030 mm (40,55″) | 1030 mm (40,55″) | 1030 mm (40,55″) | 1030 mm (40,55″) |

| Height on console (lid closed) | 1225 mm (48,22″) | 1225 mm (48,22″) | 1225 mm (48,22″) | 1225 mm (48,22″) |

| Height on console (lid open) | 1525 mm (60,03″) | 1525 mm (60,03″) | 1525 mm (60,03″) | 1525 mm (60,03″) |

| Depth | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) |

| Depth on console | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) | 640 mm (25,19″) |

| Weight | 96/211 | 96/211 | 96/211 | 96/211 |

| Input Power | 120V or 230V | 120V or 230V | 120V or 230V | 120V or 230V |

| Peak power consumption | 1200W | 1200W | 1200W | 1200W |

| Vacuum interface | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT | 10mm tube or 1/4 NPT |

| Capabilities | ||||

| Liquid mixing (< ~300k cps) | ✓ | ✓ | ✓ | ✓ |

| Paste mixing (> ~300k cps) | ✓ | ✓ | ✓ | ✓ |

| High viscosity mixing (> ~10M cps) | ✓ | ✓ | ✓ | ✓ |

| Powder mixing | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with paste | ✓ | ✓ | ✓ | ✓ |

| Mix powder with paste | ✓ | ✓ | ✓ | ✓ |

| Mix liquid with powder | ✓ | ✓ | ✓ | ✓ |

| Mixing multiple samples at once | Accessory | Accessory | Accessory | Accessory |

| Dispersion | ✓ | ✓ | ✓ | ✓ |

| Milling & pulverization | Accessory | Accessory | Accessory | Accessory |

| Stroboscopic process monitoring | No | No | No | No |

| Live material temperature monitoring | No | No | No | No |

| Cooling & temperature control | No | No | No | No |

| Variable counterrotation | No | No | No | No |

| Manufacturing optimized interface | No | No | No | No |

| Deairing & bubble removal | ✓ | ✓ | ✓ | ✓ |

| Vacuum degassing | ✓ | ✓ | ✓ | ✓ |

| Cartridge deairing | Accessory | Accessory | Accessory | Accessory |

| Syringe deairing (1 or multiple) | Accessory | Accessory | Accessory | Accessory |